Stress: All bodies offer an equal internal resistance to the externally applied forces. The magnitude of the resisting force per unit area is called stress. Its SI units are N/mm2 or N/rn2.

Tensile (or ultimate) strength: It is the ratio of maximum load to original area of cross-section.

Yield strength: It is the stress of which a material exhibits a specified deviation from proportionality of stress and strain.

Compressive strength : It is the maximum compressive stress based upon the original area that a material is capable of withstanding.

Normal Stress : The stress developed on a plane normal to it is called normal stress. Itis equal to the force acting on the body per unit normal area. Thus, a1, = -. The normal stress may be tensile or compressive depending upon the force to be either of the pull or push type. Tensile and compressive stresses together are called direct stresses.

Shear Stress : It is defined as the ratio of shear force to area parallel to the force.

Conventional (or Engineering) Stress: It is defined as the ratio of load P to the original

Natural (or logarithmic) Strain: It is defined as the change in length per unit

instantaneo length. Thus,True Strs it is defined as the ratio of load P to the instantaneous ai ea of cross-

Normal Strain: It is the strain produced under the action of direct stresses.

Shear Strain: It is the strain produced under the action of shear stresses. Shear strain, y tan

Percentage Elongation: It is the change in length per unit original length expressed as percentage, i.e. ji0 x 100, where 1 = final length and 10 = original length.

Percentage Reduction of Area : It is defined as the change in area per unit original area of cross-section A0 expressed as a percentage, i.e. — 0 x ioo where A = final area of cross-section.

Gauge length: It is the specified length of the test piece on which elongation is measured during the test. The gauge length is generally 5.65 where S0 is the original area of cross-section of the specimen.

Ductility: It is the ability of a material to deform plastically before fracture. This enables the material to be drawn into wirls.

Malleability: It is the property of metal and alloys to deform plastically under compression without rupture. This enables the material to be rolled into thin sheets.

Yield point : The first stress in a material at which an increase in strain results without an increase in stress. Mild steel has two yield points: Upper and lower yield points. This term refers to ductile materials only.

Necking: A form of shape of the localized reduction in cross-section occurring in a ductile under tension before fracture is called necking.

Permanent set : The plastic deformation which persists after the removal of the applied load is called the permanent set.

Poisson’s Ratio(v) :It is the ration of lateral strain to longitudinal stram Fot a circular —(Mid)bar of diameter d and length 1 subjected to tensile load, Poisson’s ratio, v ‘= . (bl/1)

Hooke’s Law : This law states that within elastic limits, stress and strain are proportional.

Modulus of Elasticity(E): It is defined as the ratio of normal stress to normal strain .

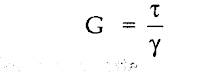

Modules or Rigidity(G) : It is defined as the ratio of shearing stress to shearing strain.

Bulk Modulus(K): It is the ratio of hydrostatic stress to volumetric strain.

Free Body Diagram: It is the diagram of only that member as if made free from the rest, with all the internal and external forces acting on it.

No comments:

Post a Comment